Food Quest: Chocolate & Spice

While Costa Rica isn’t especially know for it’s cuisine or even a particular dish, it does produce cocoa for chocolate and essential spices such as vanilla, cinnamon, allspice, tumeric and black pepper. Several of the plantations producing chocolate and spices offer tours that make them well worth a visit.

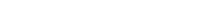

VILLA VANILLA

Villa Nueva, Manuel Antonio National Park

One of the largest producers of spices in Costa Rica is Villa Vanilla. The plantation includes 27 acres of agriculture production and 125 acres of rainforest. Crops include all major spices and cocoa, but vanilla is the primary focus.

Vanilla is the only edible member of the world’s 35,000 orchid species, and vanilla pods are the fruit of the Vanilla Orchid. Each orchid must be fertilized and processed by hand — a time-consuming, costly endeavor.

Once harvested, vanilla pods are cured in order for the vanillin, which gives vanilla its distinctive flavor, to be produced. Pods are kept warm and slowly dried for three to four months until they become pliable and turn a deep brown. Over 150 organic compounds naturally make up the flavor of vanilla. The complex nature of pure vanilla has made the production of similar-tasting artificial flavors impossible.

Villa Vanilla conducts tours through the plantation and processing facilities regularly. During the tours, visitors may sample the spices. A variety of drinks and pastry, using ingredients from the property are available to sample as well. During the spring pollination season, visitors may also observe, and assist with, the pollination of the vanilla flowers.

The vanilla, cocoa and many spices produced at Villa Vanilla can be purchased at the plantation’s gift shop or at www.rainforestspices.com. Tours can be scheduled by calling 506-8839-2721 or writing info@rainforestspices.com.

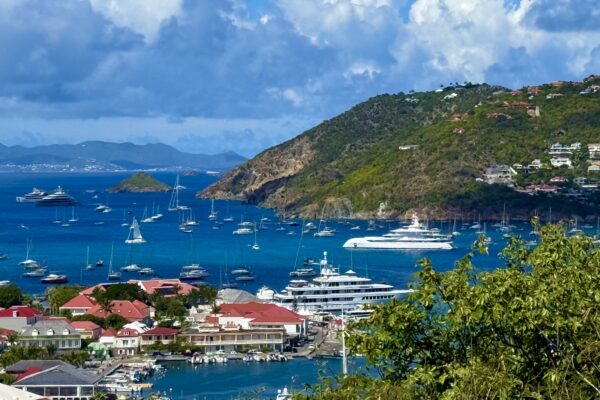

CHOCORART CHOCOLATE

Puerto Viejo at Playa Chiquita

Cacao plantations once played a prominent role in Costa Rica’s agricultural markets, but few are left today. Chocorart is one of the last fully operational plantations. Its Swiss owners welcome tourists and explain the laborious method required to produce chocolate for the candy bars and cakes we all love.

The process begins with the cacao pod, which contains anywhere from 20 to 60 seeds, embedded in a think sugary pulp.These insides are scooped out and the seeds within the pulp are allowed to ferment. The fermentation may require a week or more. Next the beans are dried slowly to reduce moisture and give the chemical reaction, that began during fermentation, time to complete.This process takes another week as well. After harvesting, fermenting and drying, the beans are roasted. The aroma is heavenly! Roasting times may vary anywhere from 30 minutes to two hours depending on the temperature and type of bean.

After roasting, shells called husks are separated from the nibs, which are the inside of the bean. The nibs are ground into a thick paste called chocolate liquor — even though there is no alcohol. Sugar is mixed into the chocolate liquor paste. Once the two are fully incorporated, it’s ready for a taste, although visitors are reminded that the mixture is unprocessed chocolate, with only minimal sugar added. It might look a bit like frosting, but it won’t be nearly as sweet.

Chocorart produces six different kinds of chocolate. Flavors such as vanilla or coffee are also introduced when the sugar is added. Shaved ginger, nuts, or cocoa nibs can be added as well. Finished products can be purchased on site.

To make arrangements for the two-hour tour, call 2750-0075 or write chocorart@racsa.co.cr